As the authorized distributor of MAXIMATOR in Indonesia, PT. Putra Andalan Perkasa is always trying to build a good and sustainable partnership with customers. Likewise with MAXIMATOR, as a leading supplier for high pressure, testing, hydraulic and pneumatic systems, and also high pressure testing unit, we provide expert consultation, design and delivery techniques, complex systems for economical solutions for special tasks.

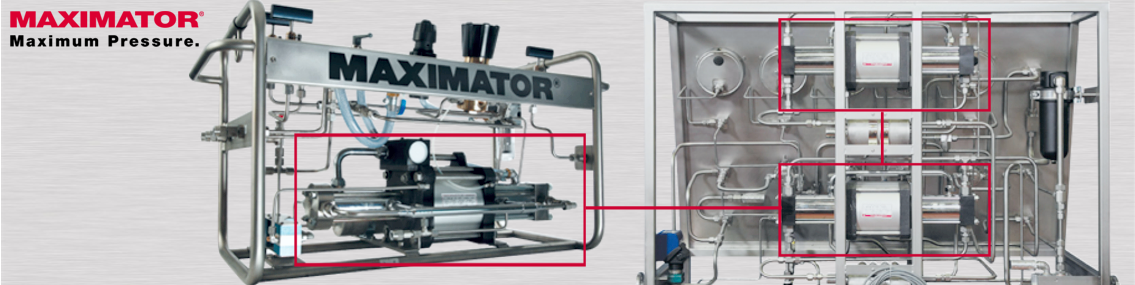

Maximator High Pressure Pumps

There are many potential applications for MAXIMATOR Pumps in mechanical engineering, oil and gas industry, chemical and pharmaceutical industry, defense, mining and construction industry, aviation and aeronautics as well as other industrial fields. Similarly in Indonesia, we as an authorized distributor of Maximator has and always serve the distribution to various fields of industry throughout Indonesia to meet your needs.

The MAXIMATOR air drive concept provides a number of benefits to you:

- Pressure regulation via manual pressure control units or pneumatically triggered valves

- Pressurised air drives, i.e. the pumps are particularly suitable for application in explosion-proof areas

- Stalling of the pump upon reaching the pre-selected ultimate pressure

- Substitution of leakages by automatic additional delivery of liquid from the pump

- No energy consumption during long pressure holding periods

- No heat loss during the pressure holding phase

- Easy installation and problem-free operation of the units. Only connections to air supply as well as suction and pressure lines are required

- Operationally reliable, easy-to-install and low-maintenance units, quiet in operation

MAXIMATOR Pumps are available in 5 sizes: M, S, G, GX, DPD. The sizes vary according to their suitability for different pumping media, wide ranging flow rates and their maximum allowable operating pressures. MAXIMATOR provides the best-suited fluid pump for each application.

Maximator High Pressure Booster

- Driven by compressed air (1-10 bar), reciprocating piston boosters (single, double acting and combined acting)

- The MAXIMATOR high pressure boosters are suitable for the oil free compression of gases and air. Industrial gases like Argon, Helium, Hydrogen and Nitrogen can be compressed

- to operating pressures of 2,100 bar (30,000 psi), Oxygen to 350 bar (5,075 psi).

As a result of the wide range of models it is possible to select the optimum booster for each application. Single stage, double acting or two stage boosters or a combination of these models can be used to achieve different operating pressures and flow capacities.

- Pressure test with gas

- Gas transfer

- Gas recovery

- Charging of nitrogen accumulators

- Supply for isolating gas systems

- Gas assisted injection moulding

- CO2 foaming

- Transfer of oxygen cylinders

- Charging of breathing air bottles

- Leak test

Maximator Air Amplifier

Driven by compressed air (1-10 bar), reciprocating piston air amplifiers, operating in accordance with the pressure intensifier principle, suitable for oil free compression of air and nitrogen, designed for pressures up to 60 bar (870 PSI), easy and safe to operate and maintain, suitable for operation in explosive proofed areas (ATEX 94/9/EG).

All PLV Air Amplifiers can be supplied with an air control unit comprising a filter, pressure regulator with pressure gauge and an air shut-off valve. The desired operating pressure can be preset by means of the air control unit in correspondence with the different pressure ratios. We can offer you a choice between a standard PLV Air Amplifier Station or a customised solution.

The compressed air from the standard air system is compressed to the desired higher final pressure. This is a simple, safe and economic mode of operation. Thus, expenditures for an in-house high-pressure system or a separate decentralised compressor plant can be saved.

The benefits of this design are:

- Selected pressure boosting upstream of individual consumers.

- Zero energy consumption after final pressure is attained.

- No electrical installations are required

MAXIMATOR Package Systems

Gas assisted molding with liquid gas supply: Supply with liquid nitrogen, Supply with liquid carbon dioxide

Gas assisted molding with gas bottle supply: Compressor Station and Control Module, Compressor- Control Module, Water assisted molding, Gasdosing Technology.