A slurry pump is specifically designed to transport abrasive or corrosive media containing solid particles. Its working principle relies on the rotation of the pump shaft driving the impeller. Under the impeller’s action, the solid-liquid mixture gains energy to generate pressure and velocity for effective material conveyance. During design, engineers prioritize the medium’s abrasiveness and particle size to ensure high efficiency and long-term stability. SANLIAN PUMP offers tailored solutions to meet diverse application needs, ensuring reliable performance under complex and variable operating conditions.

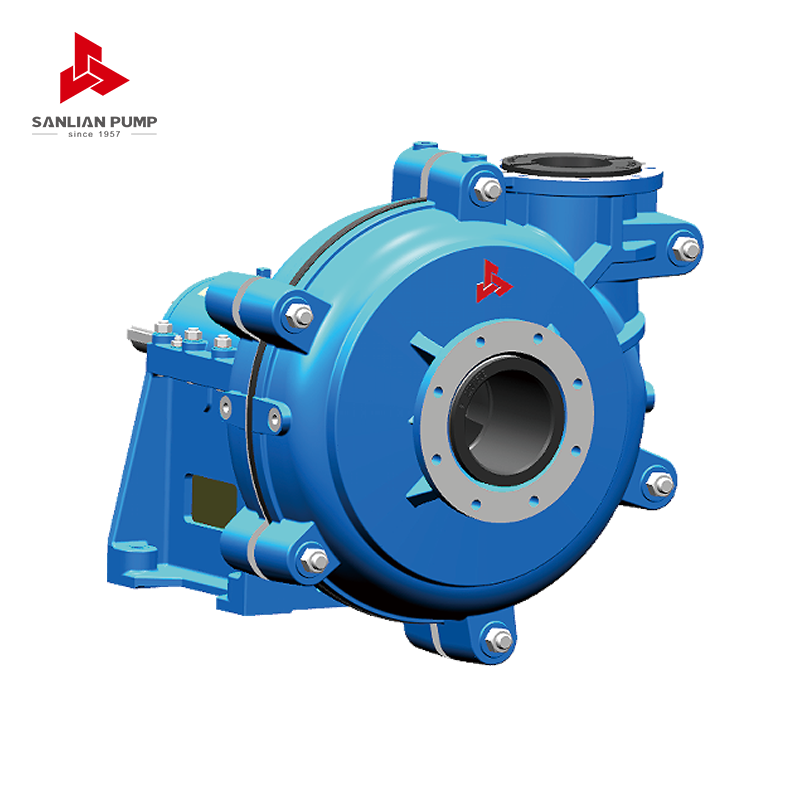

AH Series Horizontal Slurry Pumps

| Outlet Diameter | DN = 25~500mm |

| Flow | Q = 3.6~5500m³/h |

| Head | H = 5~98m |

| Operating Temperature | T≤80℃ (If it exceeds 80℃, it should be specified when placing an order.) |

| Mass Concentration | C≤60% |

The AHK series of slurry pumps are single-stage, single-suction cantilever horizontal centrifugal pumps, suitable for transporting liquids containing suspended solid particles in industrial sectors such as metallurgy, mining, coal, electricity, and building materials. These liquids include highly hard, highly corrosive, and high-concentration slurries such as concentrate, tailings, ash slag, coal cinder, cement, soil, and placer minerals.

The AHKR rubber-lined pump is designed for special working conditions with fine particles without sharp edges. High-quality wear-resistant rubber is selected, which has good wear resistance, tear resistance, impact resistance, high elasticity, and chemical stability.

The typical working conditions are as follows: the concentration of the transported slurry is ≤60%, the temperature of the medium is ≤80°C, and the solid particles are 80 to 200 meshes.

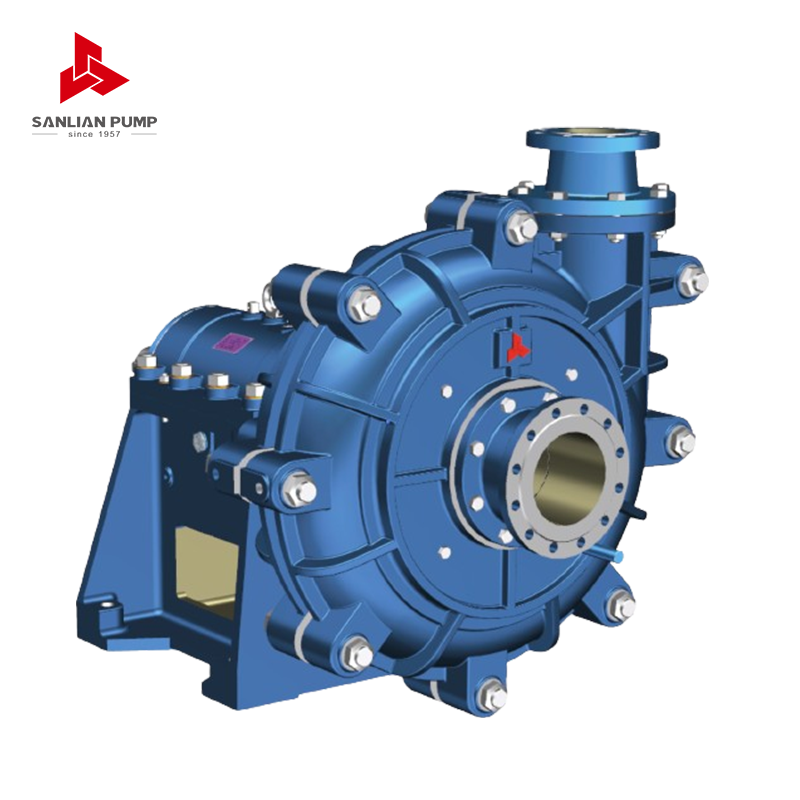

ZS Series Horizontal Slurry Pumps

| Outlet Diameter | DN = 25~300mm |

| Flow | Q = 44~2200m^3/h |

| Head | H = 16~116m |

| Operating Temperature | T≤80℃ (If it exceeds 80℃, it should be specified when placing an order.) |

| Series Connection Pressure | P = 2MPa |

The ZS series of slurry pumps adopt a horizontal, single-stage, single-suction, cantilever double-shell design. It is a specially upgraded product developed by the design team of Sanlian Pump Industry based on years of experience in centrifugal pump design. This pump features high efficiency, a reasonable structure, a spacious flow passage, strong flow capacity, high reliability, and convenient maintenance.

Aiming at complex pipeline structures, the pump's discharge port is designed to be rotatable. It can be rotated to 8 different installation positions at intervals of 45°.

In applications with long conveying pipelines, by adopting a series connection structure and coordinating with terminal speed regulation, the ZS series of slurry pumps can meet the requirements of most working conditions.

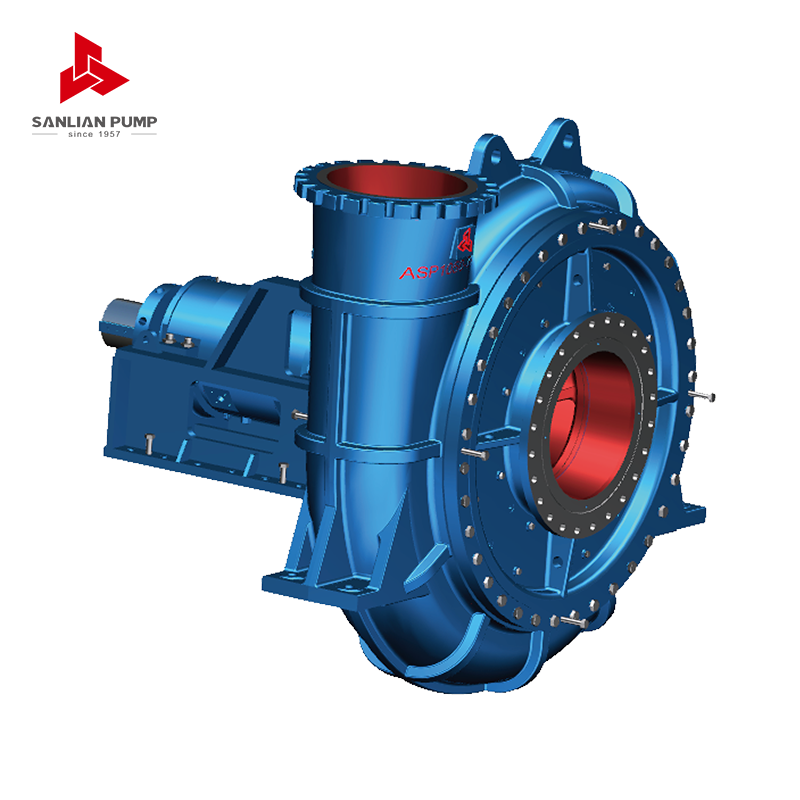

SLN Series Mud Pump

| Caliber | DN=200~1000mm |

| Flow | Q=20~25000m^3/h |

| Head | H=20~85m |

| Temperature | T=-15~100℃ |

The SLN dredging pump adopts a single-stage single-suction cantilever horizontal structure as a whole. It is a new type of mud pump independently developed for dredging and filling work in rivers, lakes and seas. This product has the advantages of light weight, excellent cavitation performance, strong abrasion resistance, spacious flow channel, convenient installation and use, etc. It can continuously transport large-particle highly abrasive mud and sand, and is suitable for various scenarios such as relay pump stations of shield systems and dredging systems of dredgers.